Top Guidelines Of 24??media

Table of ContentsFascination About 24??media24??media - TruthsA Biased View of 24??mediaThings about 24??mediaFascination About 24??media

Innovations in print technology are transforming the communications playing field when it involves quality, cost and advanced abilities. Countered printing and digital printing are the significant procedures by which print tasks are undertaken both using four-color printing techniques. Each alternative has its advantages, using various techniques to meet the requirements of varied manufacturing tasks.

Normally, this has been one of the most constant method for specifically preserving color suits, making it excellent for print runs that only require static printing such as pre-printed forms, pamphlets, flyers, service cards, and bulk postcard mailings. Nevertheless, due to the fixed nature of litho printing, it is not perfect for variable print items that will be mailed to specific recipients such as statements, letters, and individualized postcards.

How 24??media can Save You Time, Stress, and Money.

The most current developments in print technology are aiding to bring several of balanced out's advantages right into the digital printing globe genuinely changing the face of modern-day printing! There are some crucial differences in between Offset Printing and Digital Printing.

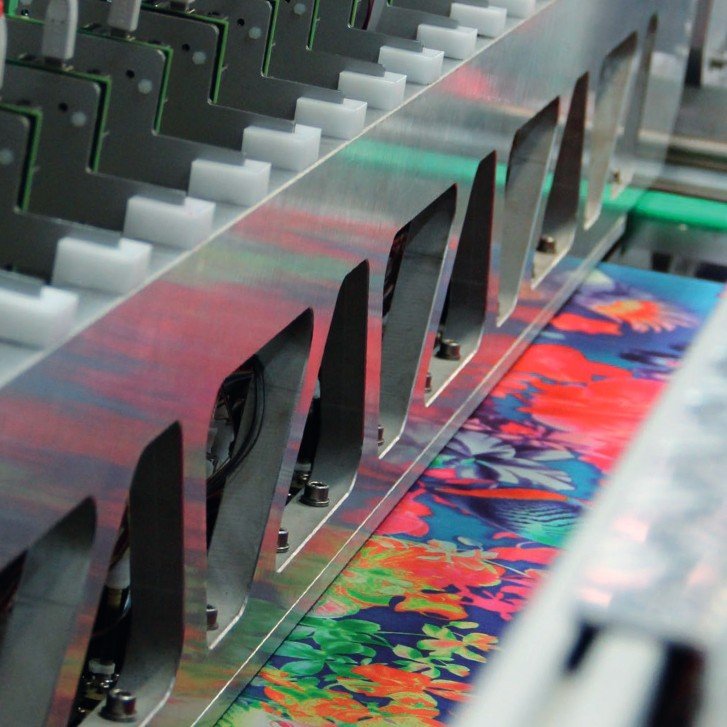

Today's digital print tools is amongst the most advanced on the marketplace. Right here are a few of the biggest benefits of using digital printing: dominate the electronic print area, with full-color printing finished in one process and seamlessly published straight from a print data. Without a lengthy set up process, the calibration time of a details task is reduced, contributing to quicker print time and total shipment.

The inkjet printing procedure has aided to transform the industry along with the quality and rate of the result. The most up to date inkjet technology can publish on traditional countered supplies with plain, silk, and glossy coatings. Top quality electronic print coupled with software-managed color administration methods includes optimum value to print pieces and makes production procedures much more trustworthy than countered.

The Ultimate Guide To 24??media

(https://myspace.com/za24media)

Specific amounts of ink and printer toner are utilized to avoid waste. Eco-friendly and eco-friendly inks and printer toners are also readily available for more lasting printing. Digital print also eliminates the need to wash plates or coverings with damaging chemicals at the end of the printing process. As the high quality of electronic print services boosts, the advantages end up being increasingly evident and advantageous.

Variable data helps services reach their specific consumers and audience with uniquely-created and personalized material. As technology improves, the top quality of digital printing has actually come to be second-to-none, with better detail, color match abilities and overall precision. Without the need to wash plates or utilize excess ink, digital printing is additionally less wasteful and usually much more ecologically pleasant.

("flexo"), include several make-ready steps to transfer an original photo to a substratum.

24??media - An Overview

Digital printing, with less moving pieces, is extra nimble than countered in this regard.

It's a way to mix your packaging and advertising and marketing methods. Decreased set-up time saves cash on the front end. And since these are not massive mass orders, smaller sized organizations can afford to print without having to fulfill the my blog greater and more pricey print thresholds of typical printing. Digital printing assists secure your brand name against counterfeiting by integrating overt and concealed services on your product packaging.

Make certain you work together with a printing and product packaging companion that has the right accreditations. While eleventh-hour printing and personalization are a massive benefit, digital may not always be the very best technique for you. Offset printing has the benefit of cost-effectiveness with huge print runs, specifically those with innovative attractive results and specialized layers.

24??media Things To Know Before You Buy

The positive plate, with its smooth surface, brings in oil-based inks and fends off water. In contrast, the unfavorable plate, with its rough structure, takes in water and fends off oil. Rubber rollers are then made use of to transfer the picture from the plate to the corrugated surface area.

Corrugated paper can in some cases show to be a challenging surface area to publish on, however Litho prints to a separate surface area and is after that laminated flooring to it, making it very easy to print premium images. It can be extremely regular, even for long terms. As a matter of fact, the more you publish, the cheaper the prices come to be for Litho.

If you have sufficient time and budget, and a large quantity of a single layout, then there shouldn't be an issue. What Litho doesn't offer you is precisely what Digital does, customization. More on that particular later. Pricey set up Longer turnaround No Variable Information Printing Smaller color range, colors can be much less intense Digital printing is the process of printing electronic images straight onto the corrugated substratum utilizing a single-pass, direct-to-corrugate strategy - Small Volume Packaging.